There are six (6) implementable clauses within ISO 9001:2015 Quality Management System Standard.

Within this series of posts over the next six weeks we will discuss the requirements to all six clauses and the correct interpretation thereof.

9.0 Performance Evaluation 9.1 Monitoring, Measurement, Analysis and Evaluation

9.1.1 General

You should note the additional requirement for your organization to evidence evaluation of the results of monitoring and measurement, not just their analysis. They should confirm that the organization has considered what, how and when to measure and that the outcomes from this decision result are ensuring appropriate process control.

They should also note a new requirement to monitor the quality performance and effectiveness of the organization’s quality management system. You should expect to see that the organization has developed a process (method, techniques, format, etc.) to identify, collect and analyze various data and information from both internal and external sources, including:

1. Quality records;

2. Monitoring and measuring results;

3. Process performance results;

4. Meeting objectives;

5. Internal audit findings;

6. Customer surveys and feedback;

7. 2nd or 3rd party audit results;

8. Competitor and benchmarking information;

9. Product test results;

10. Supplier performance information.

This ‘input’ (information and data) should reflect upon the adequacy, suitability and effectiveness of the integrated management system and its processes. The ‘output’ (result of the analysis) must provide information (understanding, insight, awareness, confidence, knowledge of, etc.). The analysis output must provide insight to:

- Customer satisfaction and perception;

- Product conformance;

- Process performance;

- Product and process characteristics;

- Trends in products and processes;

- Opportunities for preventive action;

- Suppliers and subcontractors.

Other potential or useful options might include:

- Need for corrective action;

- Opportunity for improvement;

- Competition.

Documented information and organizational knowledge that records process data should be considered for analysis. Records are evidence of system performance and should be analyzed for potential improvements.

Monitoring and measuring QMS operations and activities will establish a mechanism to ensure that your organization is meeting its policies, objectives and targets. In order to meet this requirement, your organization must perform six steps:

Step 1 – Identify the activities that can have a significant impacts and risks;

Step 2 – Determine key characteristics of the activity to be monitored;

Step 3 – Select the best way to measure the key characteristics;

Step 4 – Record data on performance, controls and conformance with objectives and targets;

Step 5 – Determine the frequency with which to measure the key characteristics;

Step 6 – Establish management review and reporting.

Establish the monitoring and tracking criteria for each activity that has a significant impact or risk and review the action plan. You should incorporate any monitoring and measurement information to cover these same activities.

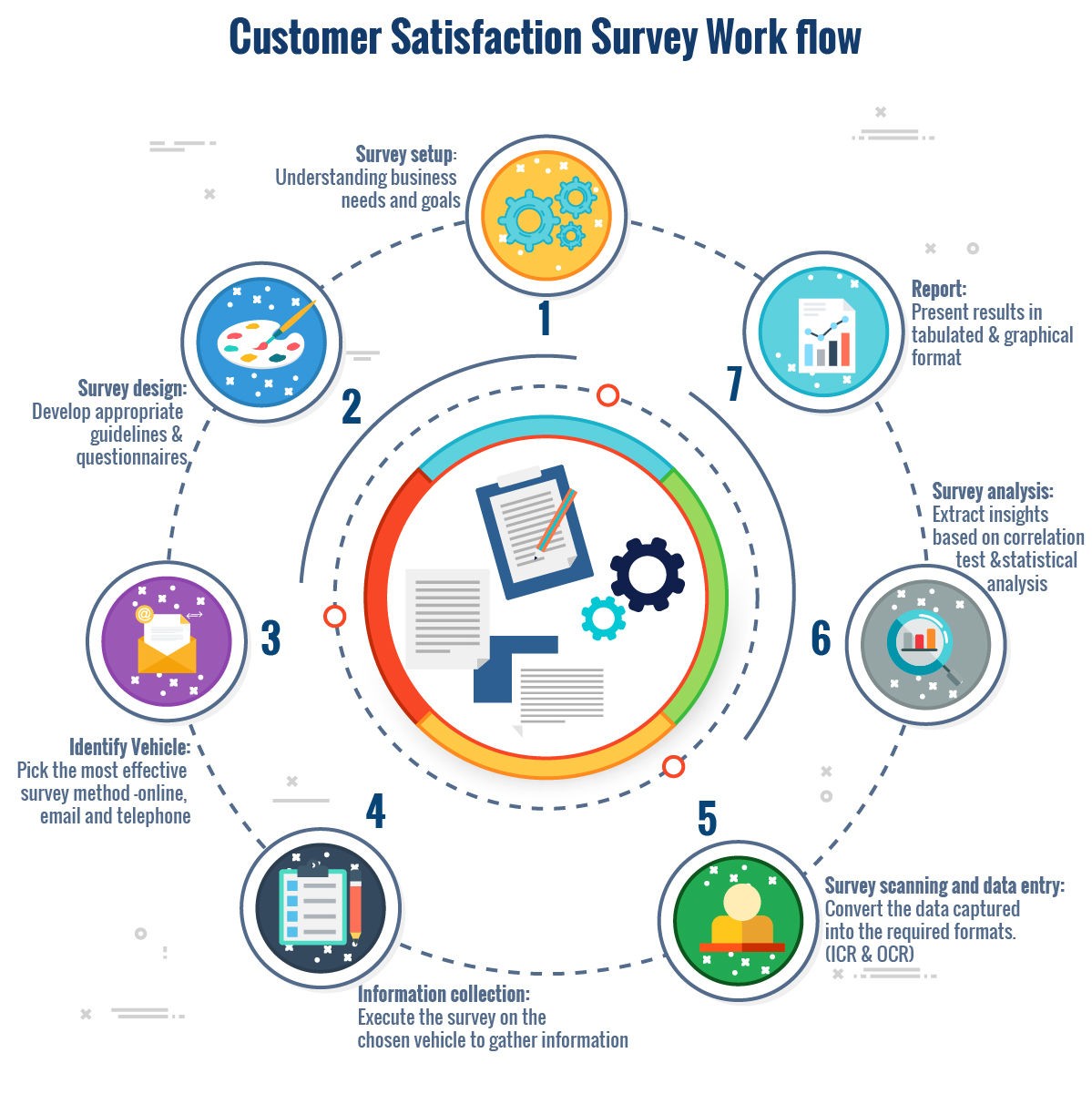

9.1.2 Customer Satisfaction

This requirement is comparable to the requirements from ISO 9001:2008 Clause 8.2.1 –

Customer Satisfaction, the change being that your organization must now solicit customer’s perception about the your organization, and its products and services. You should seek and record evidence that your organization has implemented a consistent and systematic approach to dealing with customer feedback and is obtaining information on customer perception.

Just collecting data on customer perceptions is not sufficient, you should seek and record evidence that your organization has analyzed and evaluated customer data and that conclusions have been made with regard to the effectiveness of the QMS.

1. Are there any trends?

2. Is the situation stable, improving, or deteriorating?

3. Are customer needs and expectations changing?

Both internal and external auditors will look for proof that a consistent and systematic approach has been implemented to deal with customer complaints. This approach would typically include defined responsibilities for logging and tracking complaints, clearing technical issues, determining problem causes and actions to address them. Specific examples of complaints must be sampled.

The link between the customer complaint process and corrective action also requires special scrutiny. Determine appropriate methods for monitoring and measuring customer satisfaction by:

1. Using customer satisfaction surveys;

2. Providing methods for receiving and dealing with customer feedback;

3. Providing suitable processes to monitoring trends in, and reviewing customer data.

9.1.3 Analysis and Evaluation

This requirement is comparable to ISO 9001:2008 Clause 8.4 – Analysis of Data. You should expect to see that the organization has developed a process (method, techniques, format, etc.) to identify, collect and analyze and evaluate data and information from both internal and external sources (i.e. quality records, monitoring and measuring results, process performance results, objectives, internal audit findings, customer surveys and feedback, 2nd or 3rd-party audit results, competitor and benchmarking information, product test results, complaints, supplier performance information, etc.).

This ‘input’ (information and data) should reflect upon the adequacy, suitability and effectiveness of the quality management system and its processes. The ‘output’ (result of the analysis) must provide information (understanding, insight, awareness, confidence, knowledge of, etc.). The analysis output must provide insight to:

1. Customer satisfaction and perception;

2. Product conformance;

3. Process performance;

4. Product and process characteristics;

5. Trends in products and processes;

6. Opportunities for preventive action;

7. Suppliers and subcontractors.

8. Need for corrective action;

9. Opportunity for improvement;

10. Competition.

The requirements of Clause 9.1.3 interrelate with those in clauses:

1. Management review input;

2. Improvement;

3. Corrective action;

4. Risks and opportunities.

Furthermore, any record with data that is an established part of the QMS may be considered relevant for analysis. Records are evidence of system performance and should be analyzed for potential improvements.

9.2 Internal Audit

This requirement is unchanged from the requirements of ISO 9001:2008 Clause 8.2.2 – Internal Audit. Quality professionals should note that these requirements are essentially unchanged from ISO 9001:2008 sub-clause 8.2.2.

The auditor’s role is to gauge how well this system is functioning by gathering of objective evidence of process conformance and performance. The auditee will often be a processes owner; they are the experts of that process and as such will provide an invaluable insight into the mechanics of the process.

The auditor will verify that processes are documented, implemented and understood. He will also seek confirmation that each process complies with the necessary requirements, that the process is effective and demonstrates continual improvement. Implement an internal audit programme:

1. Establish audit schedule;

2. Plan your audits;

3. Assign audit duties;

4. Review and amend the audit checklist;

5. Do auditing;

6. Prepare and submit audit report;

7. Obtain feedback from auditees.

Auditors should not necessarily expect to find a documented internal audit procedure in place. However, they must be able to access documented information confirming the implementation of an audit programme by the organization. Documented information must also be available to evidence the results of audits.

When determining how the audit programme has been designed, auditors should ensure that customer feedback, organizational changes, and risks and opportunities have been brought into consideration.

9.3 Management Review

9.3.1 General

The management review process is comparable to ISO 9001:2008 Clause 5.6 – Management Review and requires that top management periodically review the QMS to ensure its continuing suitability, adequacy, and effectiveness. The frequency or intervals of the top management review must be defined in the QMS. The management review must address the possible need for changes to policy, objectives, targets, and other elements of the QMS. The management review process must ensure that the necessary information is collected ahead of time to allow management to effectively carry out this evaluation. Information that must be reviewed includes:

1. Minutes from previous management reviews;

2. The policies, objectives and targets;

3. Results of QMS and process audits;

4. The extent to which objectives and the numeric targets were met.

Suitability and effectiveness of the QMS based possible changing circumstances that may include:

1. New or proposed legislation or regulations;

2. Changing expectations/requirements of relevant interested parties;

3. New or modified activities, products, or services;

4. Advances in technology and science;

5. Changing market preferences of buyers.

All management reviews must be documented. Observations, conclusions, and recommendations for further necessary action from the review must be recorded. If any corrective action must be taken, Top management should follow up to ensure that the action was effectively implemented.

The purpose and final outcome of the management review should be continual improvement of the IMS. As your organization’s IMS increases in its effectiveness and efficiency, your environmental performance will likewise increase.

Here’s what ISO 9001:2015 is really all about: defining a policy, creating a plan devising with relevant objectives. You then implement the system according to the plan. You then begin auditing, monitoring and measuring performance against the plan and reacting to your findings. Bi-annual management reviews are insufficient in frequency to be able react to any issues effectively.

Performance metrics should be monitored with varying frequencies, some hourly, some daily, some weekly and some monthly. Management cannot wait for six months to respond, if they do, it will be too late. Every time management convenes to review and react to performance, it is considered as a management review. Whether they are reviewing an individual’s performance, departmental programmes and projects, etc., this should be considered as valid management review.

Some companies have multiple review levels, whereby, each review may require multiple subjects and rely upon multiple metrics as inputs. Sometimes subjects are reviewed at more than one level, e.g. production numbers might be reviewed by the Production teams during daily production meetings and then by senior management, possibly weekly.

Top management might conduct weekly meetings in which they review metrics and objectives to determine if any corrective action is required. The process owner is then responsible for reporting close out progress in the meeting a week later. Undertake management reviews in order to:

1. Determine and evaluate QMS performance;

2. Determine the need for change and improvement;

3. Determine the suitability of the policies and the objectives.

9.3.2 Management Review Inputs

This now includes additional requirements for your organization to have a structured management review process that includes discussion of internal and external issue changes, and its potential effect on the strategic direction of your organization. Your organization’s management review process must also include discussion of external provider’s, and other supplier’s performance. It must also include an assessment of risk management actions.

Auditors should expect to evidence the same outputs from management reviews as at present. However, they should note that the results of management reviews can now be held in any format that the organization chooses. The management review process should focus on the following inputs:

1. Risks and opportunities (Clause 6.1);

2. Possible changes that might affect the system (Clause 6.3);

3. External provider and suppliers performance (Clause 8.4);

4. Customer satisfaction and perception (Clause 9.1.2);

5. Audit results (Clause 9.2);

6. Non-conformity and corrective actions (Clause 10.2).

9.3.3 Management Review Outputs

The management review process is comparable to ISO 9001:2008 Clause 5.6.3 – Management Review Outputs. You should seek and record evidence of outputs from the management review process, there should be evidence of decisions regarding:

1. Process improvement actions;

2. QMS improvement actions;

3. Product improvement actions;

4. Resource provision actions;

5. Revised business plans and budgets;

6. Changes to quality objectives and policies

7. Management meeting minutes.

Management review meeting minutes should be retained as documented information.

Join our mailing list to receive upcoming posts: http://www.isoqar.co.za/