Introducing SIPOC

What Is SIPOC? And how to apply it.

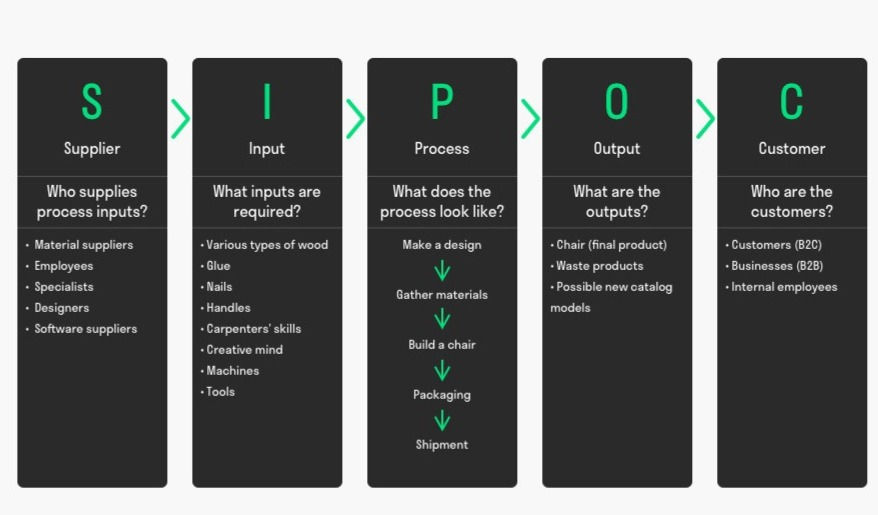

In process improvement, a SIPOC is a tool that summarizes the inputs and outputs of one or more processes in table form. It is used to define a business process from beginning to end before work begins. The acronym SIPOC stands for suppliers, inputs, process, outputs, and customers which form the columns of the table. It was in use at least as early as the total quality management programs of the late 1980s and continues to be used today in Six Sigma, lean manufacturing, and business process management.

To emphasize putting the needs of the customer foremost, the tool is sometimes called COPIS and the process information is filled in starting with the customer and working upstream to the supplier.

The SIPOC concept.

This article describes the concept of the SIPOC model in a practical way. After reading you will understand the definition and basics of this powerful quality management tool.

SIPOC is a method to properly describe the transformation process within a company that offers products and/or services. It’s a tool for process improvement that summarises the input and output of one or multiple processes in tables.

The SIPOC model method makes clear which factors influence the transformation process and which parties are involved. By mapping this, a company can find out everything that needs to be worked out to have their processes run smoothly.

The supplier supplies input in the form of raw and other materials, semi-finished products, knowledge and expertise tailored to a company’s needs. This is an important step in the process towards the eventual shape the final product or service will take for the customer. This output has to comply with and perhaps even surpass the customer’s requirements. The customer is not necessary an external party, they can also be from within the organisation.

This means supplier/customer relations can also exist within a company.

The SIPOC model helps prevent that parts of the transformation process are overlooked. The SIPOC method clarifies the process to employees who have little or no knowledge about the transformation to the final product, and it also helps employees define a new process clearly.

To clarify this tool, I created a simple example: making a butter cup.

To begin, create a table with five columns for the five words that make up the SIPOC acronym.

First, there’s the supplier, who is tasked with creating the butter cup for a customer. To do so there must be a butter cup baker, a store owner where that person works, a kitchen manager and an order taker.

That leads to the inputs, which is first the request, or order, of the butter cup. Then there’s the recipe to make it, the receipt to acknowledge the sale, the counter top to interact with the customer and other equipment. That includes a blender and probably a timer of some sort. And, of course, whatever ingredients are required to create the butter cup.

Now we’re getting to the process. It starts by receiving and preparing the order and ingredients, which must be clean, cut and sorted. Then blend those ingredients as required by the recipe. You’ll probably want to test the order before you notify the customer that the order is complete.

The output of this process is the completed purchase, the order and, hopefully, a tasty butter cup and a happy customer. You provide the receipt, and they might give you a tip for good service.

Which finally leads us to the customer, who entered your establishment with a need, in this case hunger. But there’s also the butter cup baker and even the store owner, who is a customer when out buying the ingredients.

SIPOC Model example

The SIPOC model method describes who supplies what to the production process, what exactly is being delivered by various players and what the final result is. Who the end product is intended for will also become clear. Below, various aspects of SIPOC model are explained with a practical SIPOC model example.

Supplier

This is the party that supplies products or services to the process. These can be both internal or external parties. What’s necessary for the process and what’s being used? We can find a description for this in Input. The supplier supplies, for example, materials and information. Whatever needs to be gathered before the process can start, is supplied by these parties. They can be suppliers of raw materials or knowledge, skills and information. Imagine a furniture manufacturer. The suppliers supply the wood, nails and glue, but also employees with specific knowledge, a designer of tables and chairs and a supplier of design software.

Input

In addition to the suppliers themselves, it’s now also known what they supply. The input of the process is about materials, service and information. The furniture manufacturer needs raw materials like various types of wood, other materials such as glue and nails and semi-finished products such as metal handles for closets. The carpenters’ skills are also necessary, as is the creative mind of the designer and the right input into the system by the software specialist. Machines and tools are also needed.

Process

The process itself is described in a document, manual or work instruction. By clearly describing all the steps, standard work can be delivered in the output, without a lot of deviations. On top of that, everybody involved in the process is familiar with their own actions and it’s easier to talk to each other when something doesn’t go right and correct each other. This way, all furniture in a given series that leaves the furniture manufacturer, will have be very uniform and similar in quality.

Output

The final result that comes out of the process, can be seen as the end product. In addition to the end product, waste products are also an example of the Output. The furniture manufacturer, besides furniture, also creates jobs, designs, a website with new furniture models and wood chips that leave the factory as rubbish.

Customer

The person or company you supply to, is the so-called end user. This could be the actual customer who buys furniture from the manufacturer, but it can also be the employee who has a steady job because of the factory. Customer requirements are important throughout the process. When the output doesn’t comply with the customer requirements, the quality can’t be guaranteed.

Application for Certification

Join our mailing list to receive upcoming posts: http://www.isoqar.co.za/